Polypropylene elastic yarn is an environmentally friendly material, no pollution, non-toxic, with environmental protection, light weight, chemical resistance, recyclable granulation and other characteristics. Welcome to call to negotiate business.

Inquire Now Contact UsProduct Description

Changzhou Guoxing Special Chemical Fiber Co., Ltd. is a large enterprise with environmental protection textile fiber as its core products. It is a manufacturer of polypropylene (PP) ultra-fine denier fiber with larger capacity, newer technology and better quality in China.

The advantages of polypropylene elastic wire: polypropylene elastic wire products are environmentally friendly materials, no pollution, non-toxic, with environmental protection, light weight, chemical resistance, recyclable granulation and other characteristics.

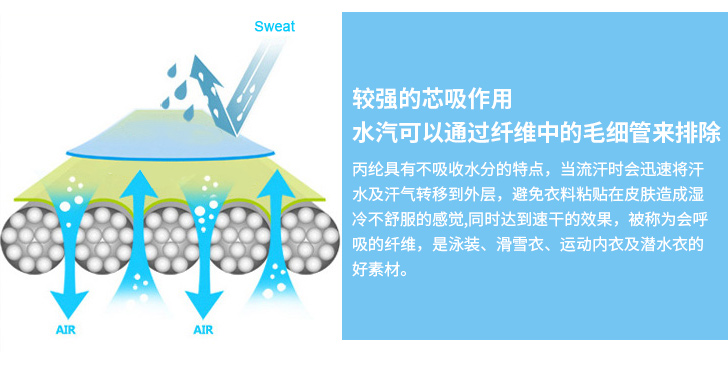

Polypropylene elastomers are used in kick guards, gloves and other products that require specific elasticity. And the hygroscopic property of polypropylene is very small, almost non-hygroscopic, and the moisture regain rate under general atmospheric conditions is close to zero. Polypropylene also has a strong core suction effect, and water vapor can be eliminated through the capillary tubes in the fiber.

The polypropylene elastic filament produced by Changzhou Guoxing Special Chemical Fiber Co., Ltd. is second only to nylon in strength, but the price is only 1/3 of nylon, and the fabric made is stable in size, good in wear resistance and elasticity, and good in chemical stability.

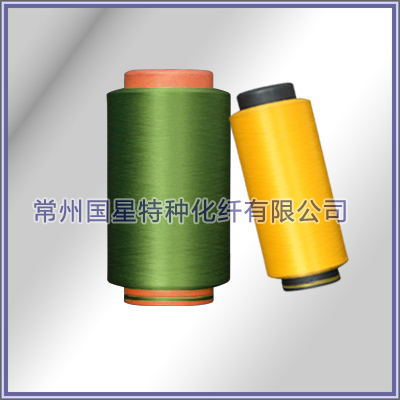

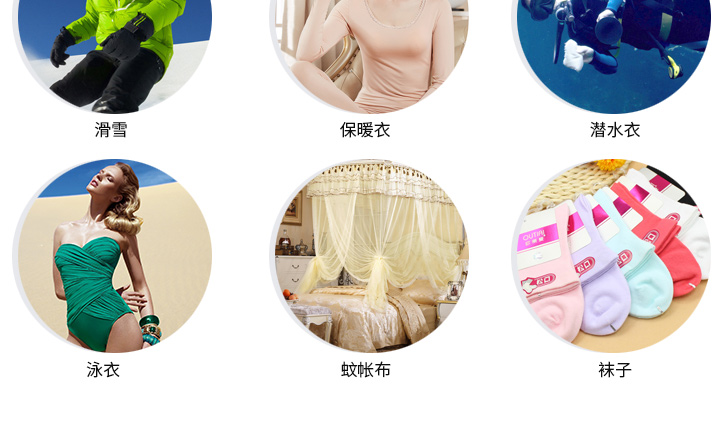

Polypropylene plus elastic silk use: can be pure spinning or mixed with wool, cotton or viscose fiber to make a variety of clothing materials. Polypropylene plus elastic silk can be used to weave a variety of knitwear such as knitted socks, gloves, knitwear, knitted pants, dishwashing cloth, mosquito net cloth, quilt, warm stuffing, webbing and so on.

Changzhou Guoxing Special Chemical Fiber Co., Ltd. specializes in the production and management of polypropylene fine denier, polypropylene fine denier DTY, polypropylene fine denier ATY, polypropylene fine denier FDY, polypropylene filament, polypropylene filament, polypropylene hollow filament, polypropylene elastic filament, polypropylene air bending filament, polypropylene drawing filament, antibacterial polypropylene filament, polypropylene air bending filament, polypropylene filament, polypropylene elastic filament.

Introduction of polypropylene filament:

1, in the polypropylene fiber fluffiness and resilience, pollution resistance is very high quality (especially after the appropriate amount of chemical storage), so that polypropylene fiber is more suitable for the supervision of the carpet.

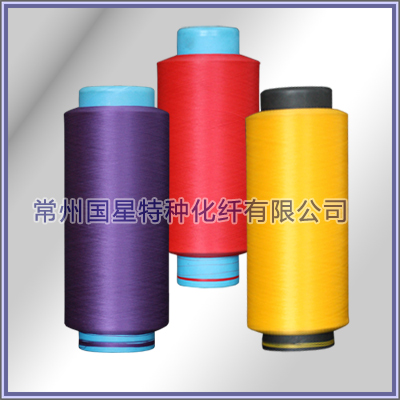

2, polypropylene elastic fabric and other elastic fabrics are not the same, it has the puffiness of acrylic, polyester anti-fouling and the softness of nylon, polypropylene filament and staple fiber can be used to produce all kinds of high elastic stretch and feel soft and elastic knitting and woven fabrics, its production process and way is more concise than spandex.

(1) Raw fabric can be made very, very easily from DTY, SDY and POY of polypropylene. The fabric with good stretch can also be woven under the premise of decent count and feel good. In addition, functional fabrics can be made by blending polypropylene and other fibers (such as PET, acetate, acrylic, cotton, wool or nylon, etc.).

(2) The weaving of polypropylene staple yarn, similar to polypropylene filament, not to mention knitted fabrics or woven fabrics, can also be made from batik yarns.

3, polypropylene fiber has the normal pressure dyeability, the conventional recommended batik temperature is 110 degrees Celsius, the batik temperature can be adjusted up and down according to the type of batik dye, because of this root it has greater advantages in blending or interweaving with wool, robinrobinic silk, cotton, nylon and other fibers.

In the conventional state, in view of the polypropylene woven fabric, sizing and washing are necessary, can be used to break down dyes, it is recommended that the temperature of batik is 100℃-110℃. In order to obtain high tensile resilient fabrics, it is necessary to heat shape the fabric at a specific temperature. And add softening agent to the fabric to soften it. After that, the final heat setting should be carried out (the setting temperature should be lower than or equal to the temperature of the previous heat setting). The resulting fabric has good stretch resilience and soft feel. In addition, pre-heating and softening is optional, but the final heat setting is required.

Related Products

Get a free product quote

Our staff will contact you as soon as possible. If you need other services, please call the service hotline: +86-519-86268808