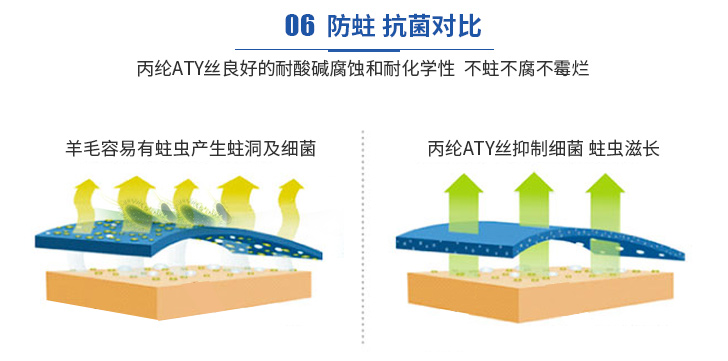

In addition to the light weight of conventional polypropylene, good heat retention, high strength, corrosion resistance, wear resistance, etc., polypropylene ATY wire for sand release and carpet also has other unique properties.

Inquire Now Contact UsProduct Description

The company's polypropylene ATY can be divided into two products:

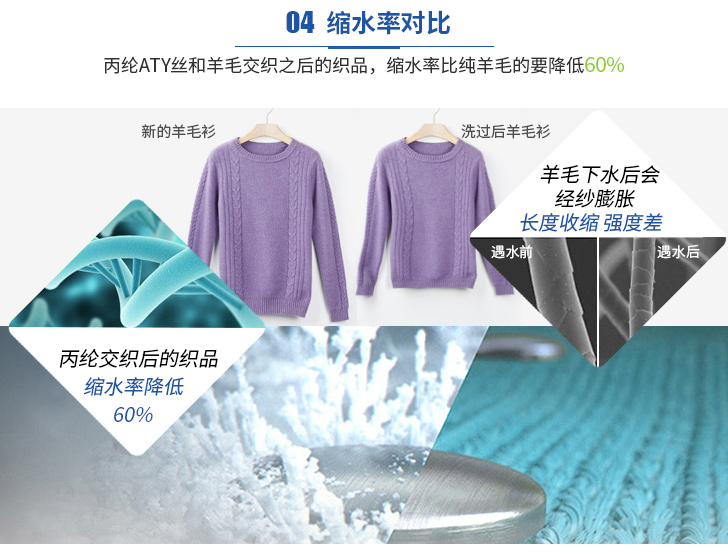

1. Polypropylene fine denier ATY yarn specification: 100D-150D, mainly used for clothing, and wool interweaving.

2. Polypropylene ATY yarn specification: 300D-3000D, used for outdoor supplies and decorative cloth. Polypropylene ATY filament specification: 450D-1500D, for outdoor tents, high sun fast type, can resist UV up to 1200 hours.

The polypropylene ATY wire produced by our company for sand release and carpet has the following advantages:

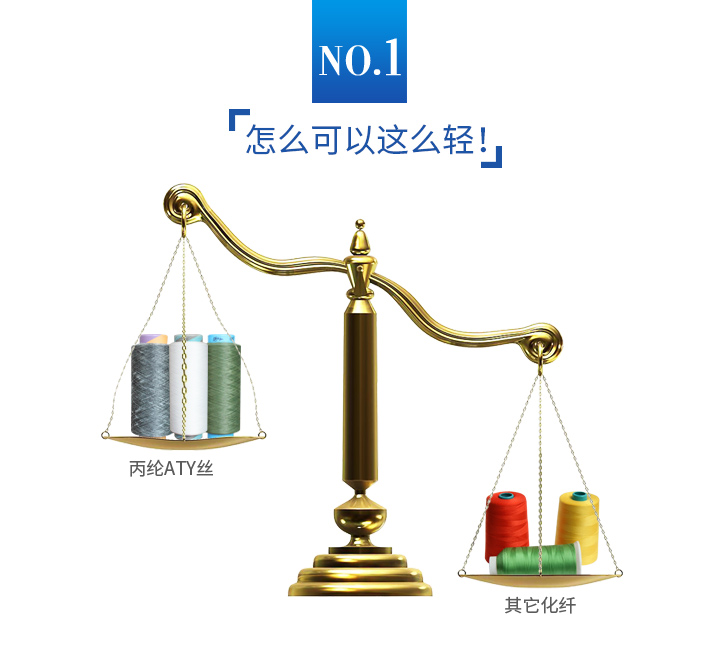

1, light fiber: less density, 40% lighter than cotton, 30% lighter than polyester, gentle lubrication;

2, warmer than wool fibers: thermal conductivity is the existing natural fibers and synthetic fibers are lower, the heat loss rate is low

3, good color fastness: the color fastness is unmatched by other fibers after dyeing and finishing;

Polypropylene ATY wire for sand release and carpet is a new variety of polypropylene fiber to imitation silk and fabric thin development, sand release, carpet polypropylene ATY wire in addition to conventional polypropylene light weight, good warmth, high strength, corrosion resistance, wear resistance and other points, but also has other unique properties. The main manifestations are as follows:

(1) Good warmth retention.

When the air thermal conductivity is 1, the thermal conductivity values of various fibers are as follows:

Cotton viscose polyacrylic wool polyester silk vinylon polypropylene

17.5 11.0 10.0 8.0 8.0 7.3 7.0 6.4 6.0

In the fabric, the lower the fiber thermal conductivity, the less heat loss of the fiber itself. Therefore, the low thermal conductivity improves its thermal function. As can be seen from the above, the thermal conductivity of polypropylene fiber is low, so its warmth is better than other fibers.

(2) Impeccable green environmental protection

Polypropylene fiber is made of hydrocarbon polymerization, so it has good skin affinity; Can be completely decomposed naturally, combustion will not produce harmful gases, will not cause any allergic reaction. That is, green fiber refers to the entire product life cycle, including the preparation of raw materials to the entire process of finished products, as well as the disposal of waste fibers after discarding, functional fabrics will not have adverse effects on the environment. First of all, the raw materials of the fiber are green and environmentally friendly and compatible with the environment: Secondly, the production and processing process of the biomass fiber obtained from the biomass raw materials must be green and environmentally friendly.

(3) Good resilience

The elastic recovery rate of polypropylene is 96% ~ 1O0%, slightly lower than that of nylon (98% ~ 1O0%). Polypropylene fiber fabric has good wrinkle resistance, and can be washed and worn.

Related Products

Get a free product quote

Our staff will contact you as soon as possible. If you need other services, please call the service hotline: +86-519-86268808