Sand release, carpets Polypropylene ATY silk

I produced the sand release, carpets Polypropylene ATY silk concrete the following advantages:

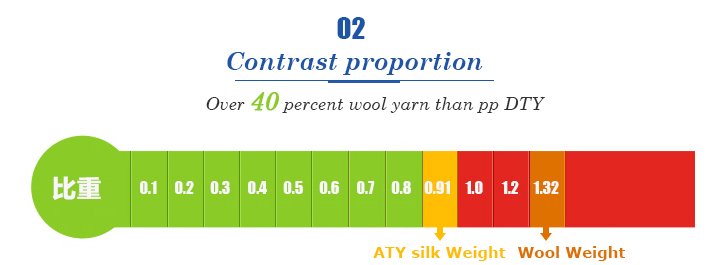

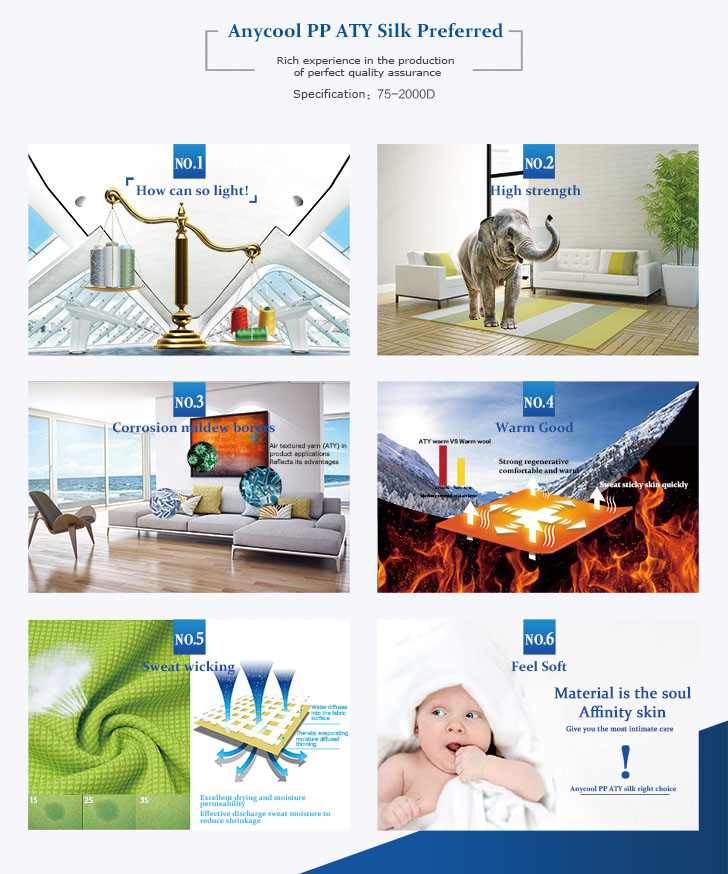

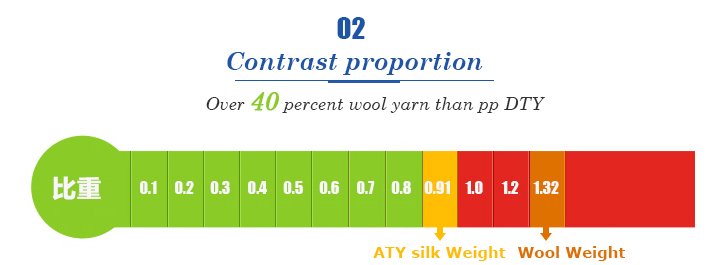

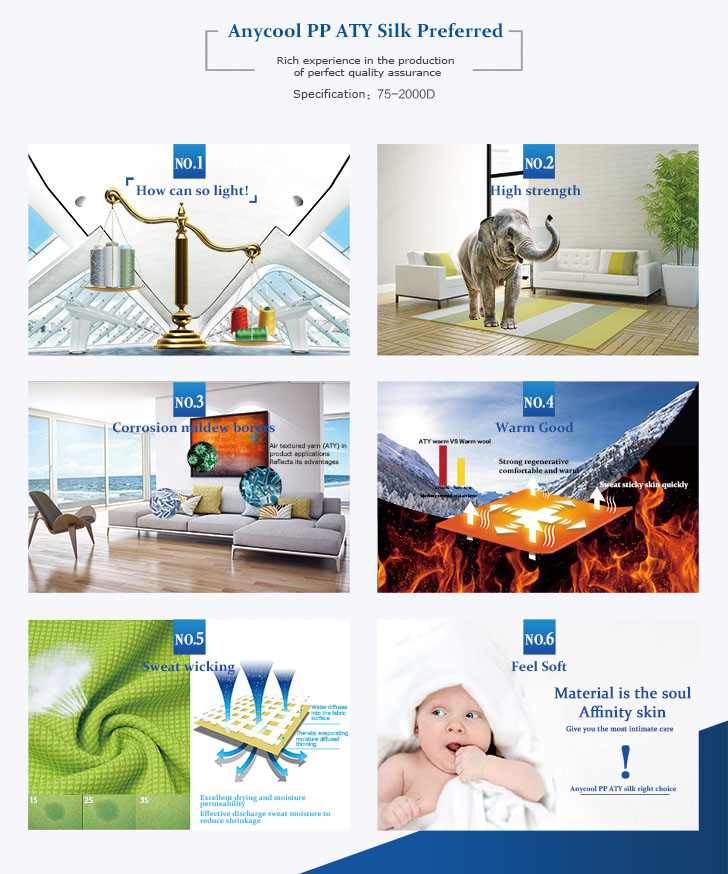

1, the lightest fiber: minimum density, weight 40% lighter than cotton, 30% lighter than polyester, soft lubrication;

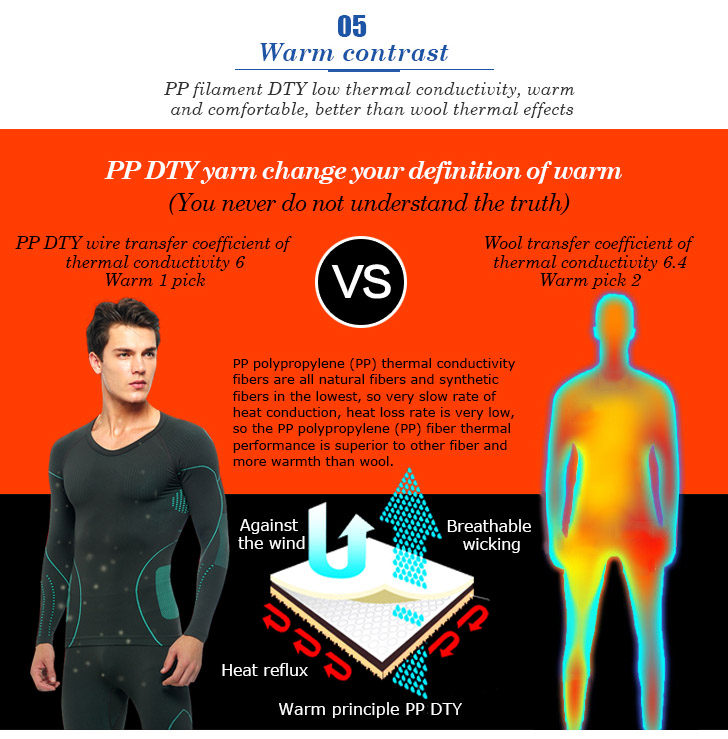

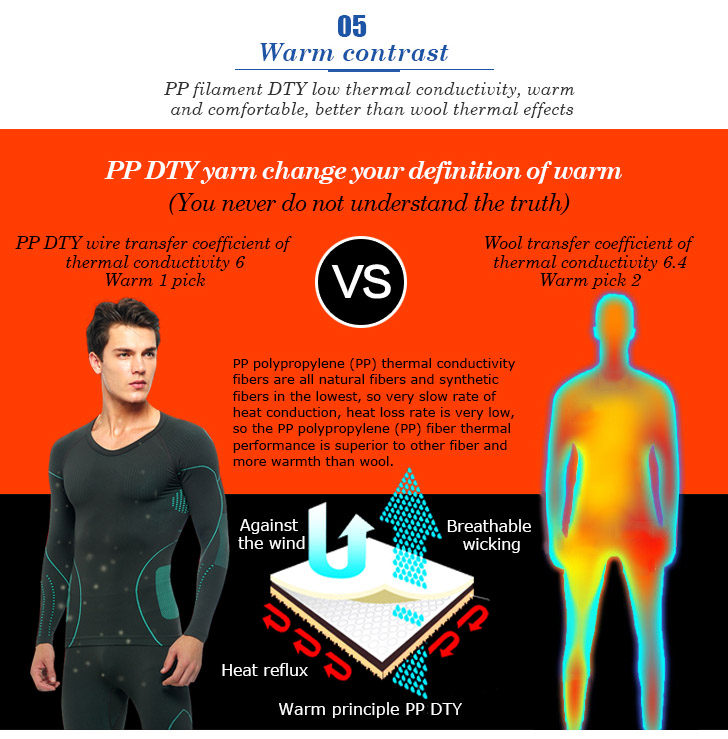

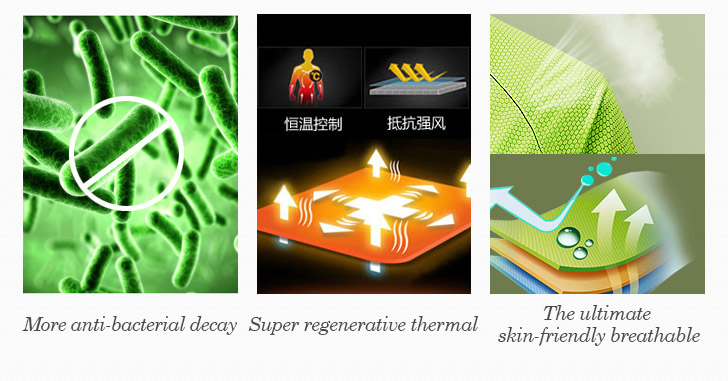

2, more warm than wool fibers: thermal conductivity is existing natural fibers and synthetic fibers lowest, low heat loss rate

3, good color fastness: dope dyeing, color fastness, after dyeing and other fiber can not be compared;

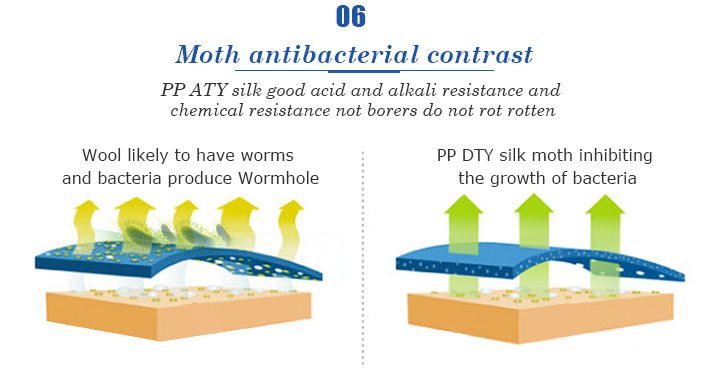

Sand release, carpets Polypropylene ATY new varieties of silk is silk and polypropylene fiber to the development of thinner fabric, sand release, carpets Polypropylene ATY silk in addition to the proportion of conventional polypropylene light, warm and good, high strength, corrosion resistance, and so a little wear, but also has other unique properties. The main performance is as follows:

(1) there is good insulation.

Thermal conductivity of air is 1, all kinds of fiber thermal conductivity values as follows:

Cotton viscose polyester nylon acrylic silk wool polypropylene polyvinyl alcohol

17.5 11.0 10.0 8.0 8.0 7.3 7.0 6.4 6.0

In the fabric, the lower the thermal conductivity of the fiber, the less heat loss of the fiber itself. Therefore, the low thermal conductivity improves its thermal features. As can be seen from the above, the lowest thermal conductivity of polypropylene fibers, so it's warm and it is superior to other fibers.

(2) impeccable green environmental protection.

Polypropylene fiber is formed by the polymerization of carbon and hydrogen, so it has good skin-friendly; naturally completely decomposed, combustion does not produce harmful gases, will not cause any allergic reactions. That green fiber refers to the disposal of the entire product life cycle, including the preparation of raw materials to finished the whole process plus formula, and after discarding waste fiber, functional fabrics do not adversely impact on the environment of the fiber. The first is the fiber raw material green, compatible with the environment: Secondly, the use of raw material production and processing of biomass fiber materials obtained shall be green.

(3) there are good elasticity.

Elastic PP recovery rate 96% ~ 1O0%, slightly lower than nylon (98% ~ 1O0%). Polypropylene fabric has good wrinkle resistance, and have to wash and wear characteristics.

Special Chemical Fiber Co., Ltd. Changzhou Guoxing main production and operation: polypropylene fine denier DTY yarn, polypropylene ATY yarn, polypropylene filament FDY, DTY fine nylon yarn, polyester filament DTY fine, functional fabrics, functional clothing with a polypropylene fine denier DTY silk, outdoor fabric with polypropylene fine denier DTY yarn, fine denier DTY Polypropylene thermal underwear silk, outdoor tent shade Polypropylene ATY silk, sand release, carpets Polypropylene ATY silk, wool warm wins ATY yarn denier polypropylene, bags, ribbon Polypropylene FDY wire, car seat with polypropylene FDY yarn, rope, wire harness with polypropylene FDY, DTY yarn denier nylon underwear, underwear denier polyester DTY yarn, single wizard wet fabrics, warm fabrics.

+86-519-86266888

+86-519-86266888 gxhx888@126.com

gxhx888@126.com